Pegas-Gonda band saw machines

Solutions for all your cutting needs

Are you looking for band saw solutions that are just right for you?

Band saw machines for cutting metal

We are the official dealer of Pegas-Gonda. Through us you can get band saw machines and spare parts. Contact us and let's find the best solution for you!

Pegas Gonda is a Czech family company that specializes in the development of cutting technology and the manufacture of band saws. Pegas Gonda manufactures band saws that are suitable for cutting metal and other necessary machines.

Pegas Gonda builds and manufactures the machines itself together with technicians, engineers and designers. The machines use state-of-the-art technology based on current regulations and environmental friendliness.

Product range

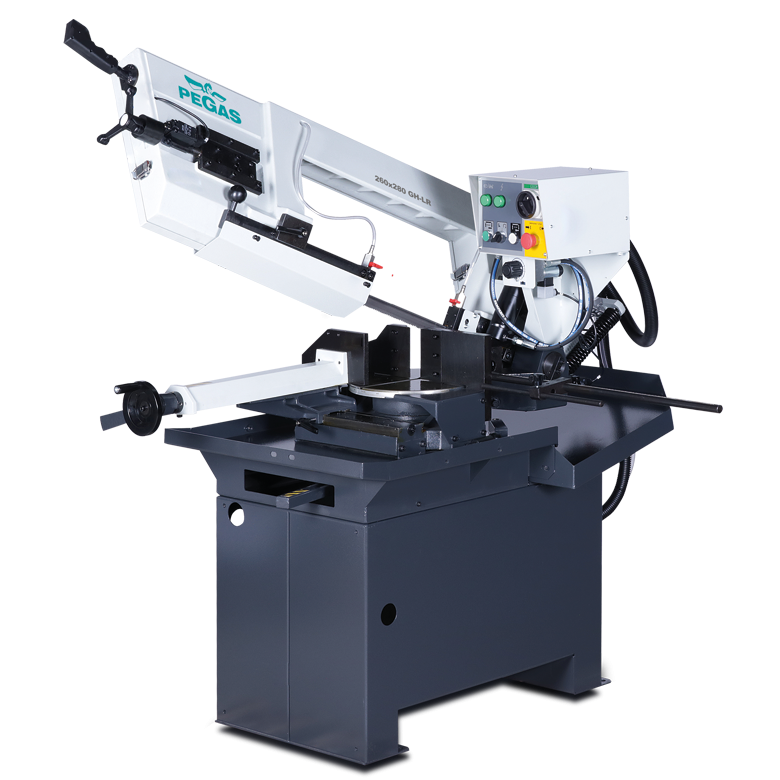

Gravitational band saw machine

Manually controlled quick clamping vice, cut is regulated by a hydraulic damper and a restrictor choke valve. A course of a cut is not influenced by a human factor and it causes a higher bladelife. A operator starts a machine pressing button START and sets a cutting speed. After finnishing the cut machines stops itself automatically and an operator lifts the arm manually to the start posittion. Feeding of material is manual. Angle cuts are possible by arm turning.

Semi-automatic band saw machines

A hydraulic semiautomatic band saw machine SHI with a complete hydraulic controll. The machine is equipped by a controll system and by a hydraulic agregate which after the starting a cycle controlls vice clamping, cut, arm lifting to a selected location and vice opening. The arm of machine is pushed towards the cut by a double acting hydraulic cylinder with a possible regulation of a press and rate of flow. Material is manually manipulated. Turning arm for angle cuts.

Automatic band saw machines

All working movements of an arm, a vice and feeders are manipulated by a hydraulic agregate. The arm is pushed by towards the cut by a doubleacting hydraulic cylinder. A speed and a force of a working movement are regulated. There is possible to make a lot of feeds. Number of pieces is set in the controlling panel, setting of a lenght is made manually. It is possible to choose an automatic or a semiautomatic regime where all movements are controlled independently. Angle cuts are possible.

Horizont band saw machines

SHI / X: Highly productive, semi-automatic dual column band saw machine. The saw is designed for cutting material in both straight and angular cuts, angular cuts adjustable 150° left, 90° perpendicular, 30° right (+/- 60 degrees). The saw is designed for cutting bars of solid material and profiles. Saw is used in series production in industrial plants. The saw is designed for cutting straight bars of steel material.

A-CNC / X-CNC: Highly productive, automatic dual column band saw with multiple material feeding The saw is designed for cutting material in both straight and angular cuts, angular cuts adjustable 150°left, 90°perpendicular, 30°right (+/- 60 degrees). The saw is designed for cutting bars of solid material and profiles. Saw is used in series production in industrial plants. The saw is designed for cutting straight bars of steel material.

Katana automatic band saw machines

It is a highly efficient automatic hydraulically controlled band-saw with multiple material feeding. The band saw machine is designed for cutting in automatic cycle perpendicularly as well as angularly. It enables angle cuts to the right 0 - 60 degrees and left 0-45 degrees. Automatic turning to angular cuts is a pert of cutting.

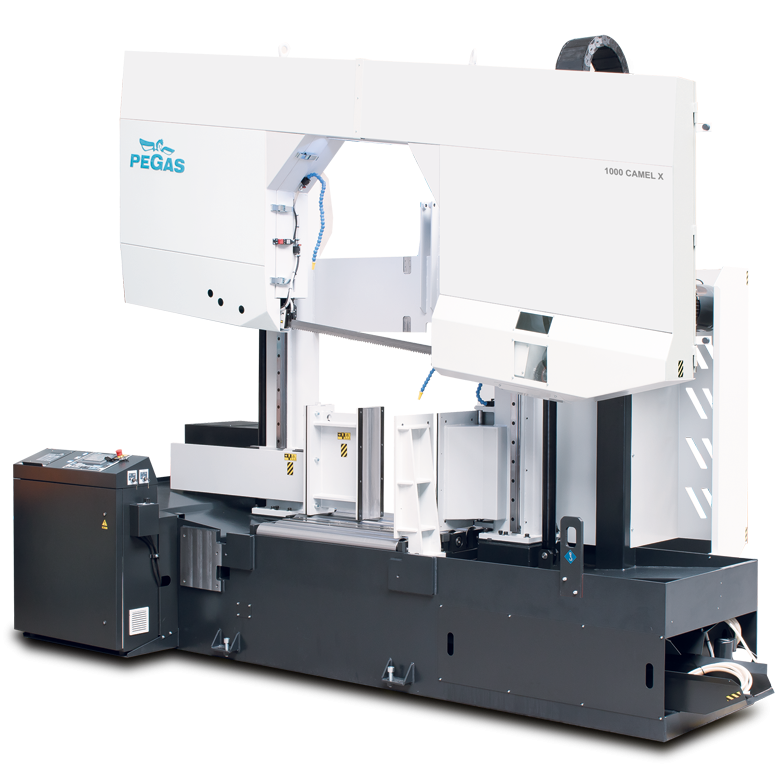

Camel band saw machines

X: Semiautomatic, hydraulically manipulated two column band saw machine. An unique construction of the band saw machine with three pulleys for leading of the blade. With the blade that is 8 grades sloped against the level guarantee high-efficiency of cutting. The machine is designed for vertical cuts. Highly efficient machine for cutting of construction steel of profile type. Secondary can be used for hardened material cutting.

X-CNC: Automatic two column band saw machine with complete hydraulic control. The machine is designed for vertical cuts. An unique construction of the band saw machine with three pulleys for leading of the blade. With the blade that is 8 grades sloped against the level guarantee high-efficiency of cutting. Highly efficient machine for cutting of construction steel of profile type. Secondary can be used for hardened material cutting.

Herkules semiautomatic band saw machines

Two-column band saw machines for vertical cuts. There is the construction with the pre-tight linear bearings.This rugged machine is suitable for cutting of full materials with the attention to the cutting performance. The hydraulic agregate controlls all working functions of the semiautomatic machine. CNC= the completely numerically controlled automat with the material feeder with the possibility of setting of several programms for setting of numbers and lenghts of cutted materials.

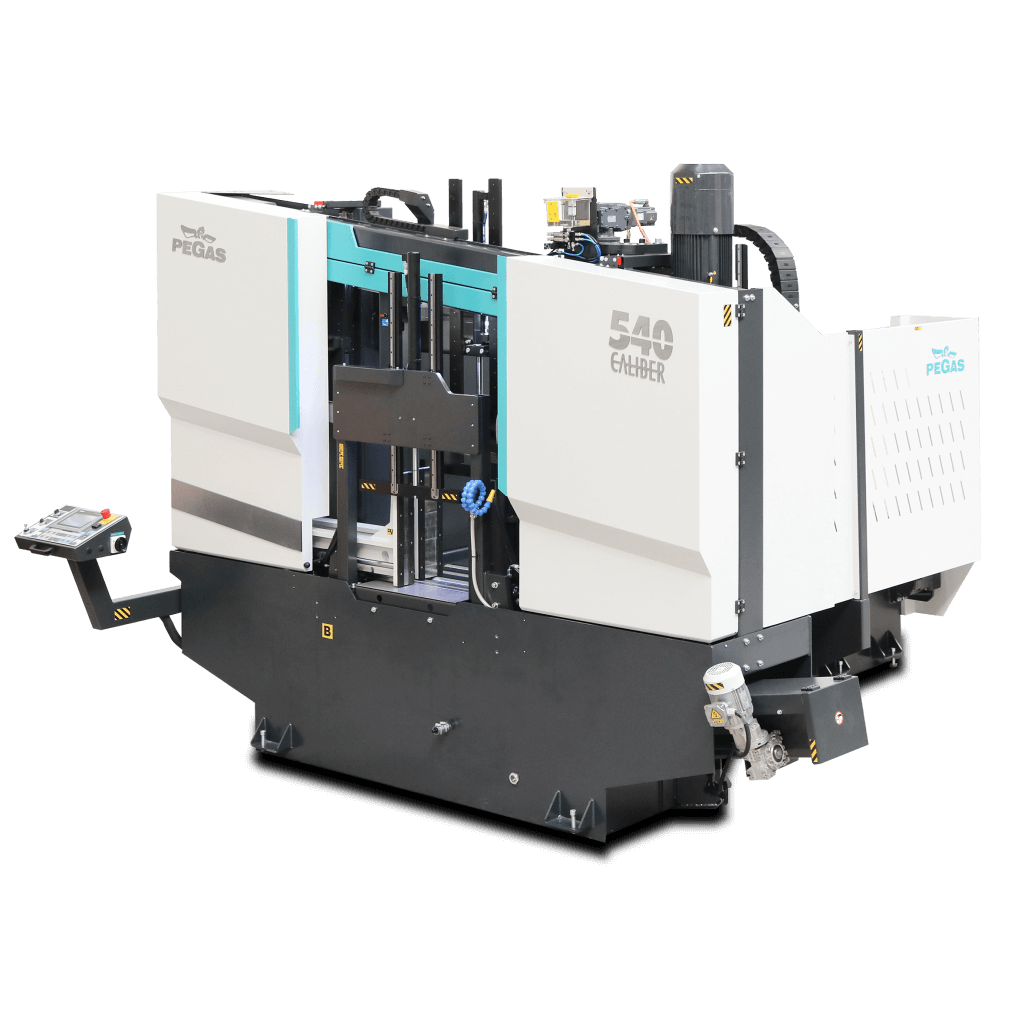

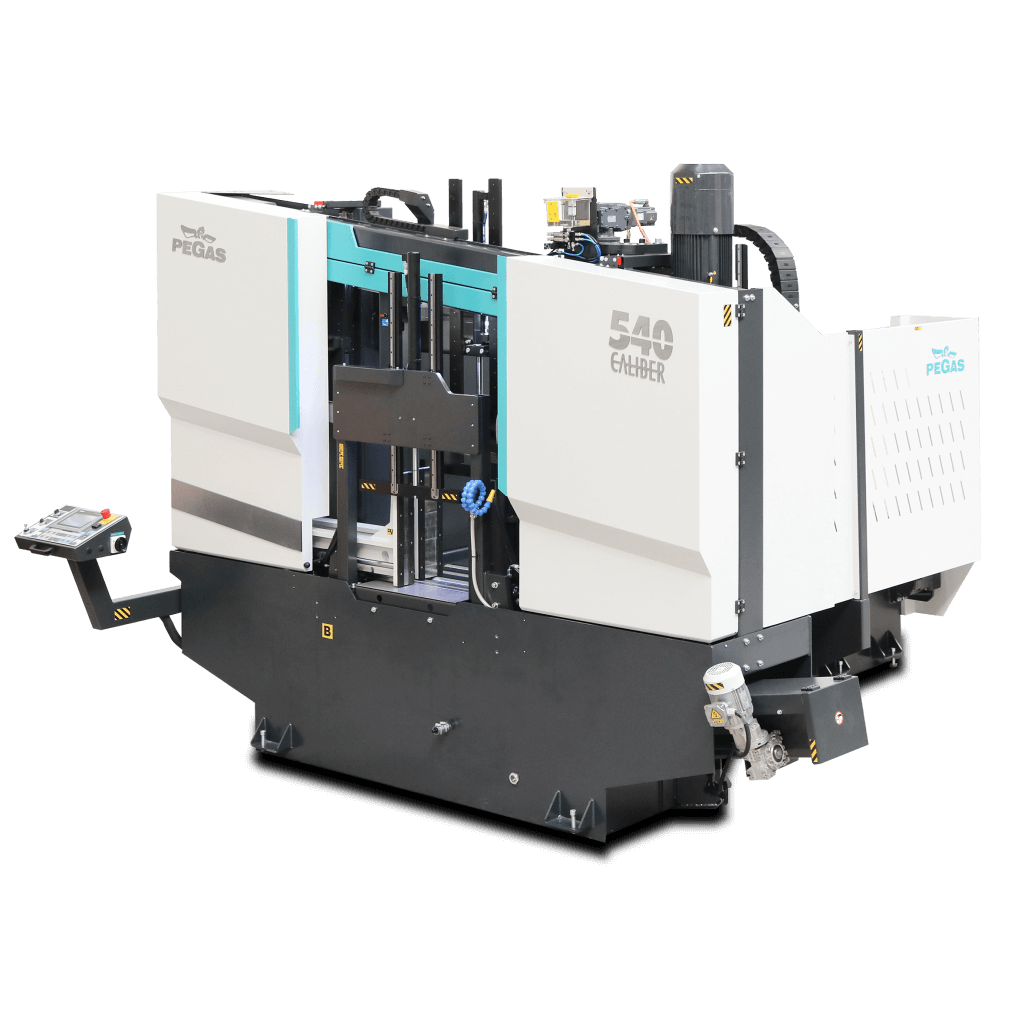

Caliber automatic band saw machines

Highly productive, automatic dual column band saw with multiple material feeding. The saw is designed for cutting material in straight cuts. The saw has the concept FVC = feeder – cut - main vice. The FVC concept enables cutting of single bars and bundles in an automatic cycle with short residue. The saw is used in serial production in industrial plants and it can cut a wide range of material grades including stainless and tool steels due its robust design. The saw is designed for cutting straight bars of steel material!

Thor automatic band saw machines

It is a highly efficient automatic,band-saw with multiple material feed. Bandsaw is designed for performance cutting very hard and tough materials. This bandsaw is using extremely robust construction optimized with target to get maximum rigidity of machine and minimum vibrations. Stroke of frame and feeder stroke is realized by sharpen ball screws. Machine guarantees maximum possible power a precision. The machine is designed for vertical cuts. It is suitable for serial production in industrial premises. The machine is designed to saw steel materials, but also non-ferrous and light metals. However, we recommend consulting the manufacturer about this option. No other materials may be sawn without approval from the manufacturer. Conception of bandsaw is FCV= feeder-cut-main vice. Conception FCV enable cut material in automatic cycle with shortest possible end. Don´t need to measure and cut ends of bar in semi-automatic cycle.

Contact us

Pegas Gonda – Band saw experts for over 30 years

Pegas Gonda is a family-owned engineering company from the Czech Republic. For over 30 years, Pegas has been developing and manufacturing high-quality band saws for metal cutting, which are used worldwide for industrial and production needs.

Product development combines the expertise of engineers and designers with the latest technologies, environmentally friendly solutions and current legislation. Pegas's own production is supported by all key stages: cutting, welding, machining, painting and assembly. This ensures high quality and a long service life for all products.

Since 2000, Pegas has operated in accordance with the ISO 9000 and ISO 9001 quality systems. This guarantees transparent and responsible operations. Pegas also offers customers comprehensive maintenance and fast support.

Why choose Pegas Gonda?

- Over 30 years of experience in manufacturing band saws

- Family business values and responsibility

- High-quality production in our own factory (6500 m²)

- Certified ISO 9001 quality system

- Innovative and environmentally friendly solutions

- Over 15,000 sawmills in use around the world

So get in touch and let's find the right band saw solution for you!